Brick-Making Machine: Core Equipment in Modern Building Materials Production

Against the backdrop of rapid development in the construction industry, brick-making machines—as core equipment for producing wall materials—have gradually replaced traditional manual brick-making methods. With their high efficiency, environmental friendliness, and versatility, they have become a key driver in the industrialization and green transformation of the building materials sector. These machines not only convert raw materials like cement, sand, gravel, fly ash, and construction waste into bricks meeting building standards but also produce products of varying specifications and shapes according to demand. They find extensive application in residential construction, road building, municipal engineering, and other fields.

一、 Core Classification of Brick Making Machines: Categorized by Forming Principle

Currently, brick making machines on the market are primarily divided into two major categories based on forming methods:“Hydraulic Brick Making Machines”and“

Vibration Brick Making Machines.”These two types exhibit significant differences in working principles, performance characteristics, and applicable scenarios, catering to diverse production requirements.

1.Hydraulic Brick Making Machine

Hydraulic brick presses utilize “hydraulic transmission” as their core power source, employing high pressure generated by the hydraulic system to compress raw materials into shape. They represent the mainstream equipment in current mid-to-high-end brick production lines. Their advantages include:

Stable forming pressure: The hydraulic system precisely controls pressure (typically 15-30MPa), resulting in dense internal brick structure, high compressive strength (up to 15-30MPa), low water absorption, and suitability for load-bearing walls.

High product precision: Precise mold positioning ensures minimal dimensional deviation (within ±1mm), with smooth surfaces requiring no secondary processing;

Low noise and minimal wear: Smooth hydraulic transmission operates below 70 decibels, while core components (e.g., hydraulic pumps, cylinders) boast service lives of 8,000-10,000 hours, reducing maintenance costs.

Suitable applications: Large-scale brick factories, high-standard construction projects (e.g., high-rise buildings, bridges). Capable of producing high-strength products including standard bricks, hollow bricks, and permeable bricks.

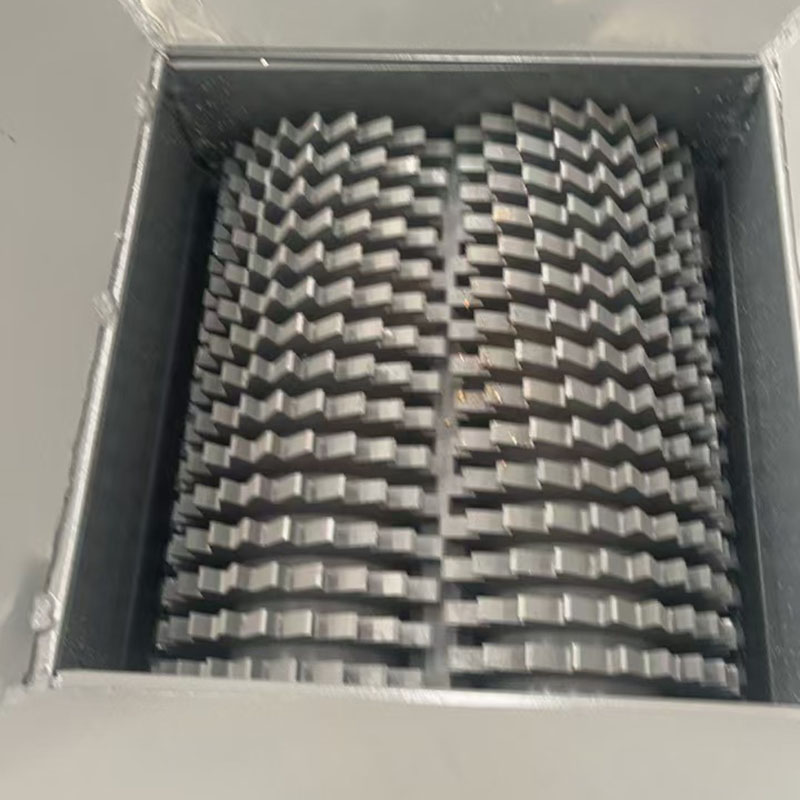

2. Vibration Brick Machine

Vibration brick machines utilize high-frequency vibrations (50-60Hz) generated by “vibration motors” to compact raw materials within molds, making them suitable for small-to-medium-scale production. Key features include:

High production efficiency: Short vibration molding cycle (30-60 seconds per mold), hourly output reaching 2,000-5,000 standard bricks;

Low equipment cost: Relatively simple structure without complex hydraulic systems, initial investment only 50%-70% of hydraulic brick machines;

Strong adaptability to raw materials: Can process coarser-grained materials without fine grinding.

Suitable applications: Small-to-medium brick factories and rural construction projects. Primarily used for producing non-load-bearing hollow bricks, paving bricks,and similar products. However, brick strength is relatively low (typically 8-15 MPa) and requires natural curing to enhance performance.

二. Brick-Making Machine Workflow

A complete brick production line comprises not only the main brick-making machine but also requires integrated “raw material processing systems,” “conveying systems,” and “curing systems” to form a closed-loop production process. The specific steps are as follows:

1. Raw Material Pre-processing: Sand, gravel, cement, and fly ash (or crushed construction waste) are mixed in specified proportions. Water is added to achieve a moisture content of 12%-18%. The mixture is thoroughly blended in a mixer to form a uniform wet material, preventing clumping or segregation.

2. Material Distribution and Molding: The conveying system feeds the wet mixture into the mold cavity of the brick-making machine. Hydraulic pressure (or vibration from a motor) compacts the raw materials within the mold. After mold opening and closing, the formed brick blank is ejected.

3. Palletizing and Curing: Robotic arms or manual labor stack the green bricks onto curing racks. These are then transferred to a curing chamber (temperature 20-25°C, humidity ≥80%) for 7-14 days, or undergo natural curing for 21 days, to achieve the design strength standard;

4. Finished Product Inspection and Shipping: Cured bricks undergo compressive strength and dimensional deviation testing. Qualified products are packaged and stored in the warehouse, awaiting shipment.

三. Technical Advantages and Industry Value of Brick-Making Machines

Compared to traditional manual brick-making (such as clay-fired bricks), modern brick-making machines offer breakthrough improvements in “environmental friendliness,” “cost-effectiveness,” and “functionality,” supporting sustainable development in the construction industry:

1. Green and Eco-Friendly, Reducing Resource Consumption

Traditional clay-fired bricks require extensive excavation of clay from farmland, and the firing process emits smoke and dust, polluting the environment; Modern brick-making machines utilize industrial solid waste like fly ash, slag, and construction debris (up to 30%-50% of raw materials), transforming waste into valuable resources. Without high-temperature firing, each ton of bricks saves 15-20kg of standard coal and reduces CO₂ emissions by 50-60kg, aligning with national carbon neutrality and carbon peaking policies.

2. Energy Efficiency and Cost Reduction

Manual brick production yields only 200-300 bricks per worker daily, whereas a medium-sized brick machine can produce 6,000 standard bricks per hour—equivalent to the output of 30-40 manual workers—significantly reducing labor costs. Additionally, the high-pressure forming technology of hydraulic brick machines reduces cement consumption (saving 10%-15% compared to traditional methods), further controlling raw material costs.

3. Flexible and versatile, accommodating diverse needs

As architectural designs diversify, brick machines can produce products of different specifications and uses by changing molds: such as 240×115×53mm standard bricks, 390×190×190mm hollow bricks, permeable bricks with 15%-20% water permeability, and even decorative options like stone-effect bricks and grass pavers. This versatility meets diverse requirements for residential walls, municipal roads, and landscape projects.

四、Development Trends of Brick-Making Machines: Intelligent and Green Upgrades

Currently, brick-making machines are advancing toward “intelligent control,” “full-process automation,” and “higher solid waste utilization rates.” On one hand, by installing PLC control systems and touchscreen interfaces, they achieve automation in raw material mixing, pressure regulation, and production output tracking, reducing manual intervention. On the other hand, some enterprises have developed “zero-emission” brick production lines that recycle curing wastewater and dust, further minimizing environmental impact.

In essence, brick-making machines are not merely tools for building material production but core equipment driving the construction industry’s transformation from “high-consumption, high-pollution” to “green, efficient, and intelligent.” As technology continues to evolve, these machines will play an increasingly vital role in new urbanization and infrastructure development, providing robust support for sustainable construction.