A non-fired clay brick machine is an eco-friendly equipment designed for manufacturing construction bricks without the high-temperature firing process. Utilizing materials such as fly ash, slag, construction waste, or natural soil, it produces bricks through high-pressure compaction and natural or steam curing. This method significantly reduces energy consumption and carbon emissions compared to traditional fired brick production.

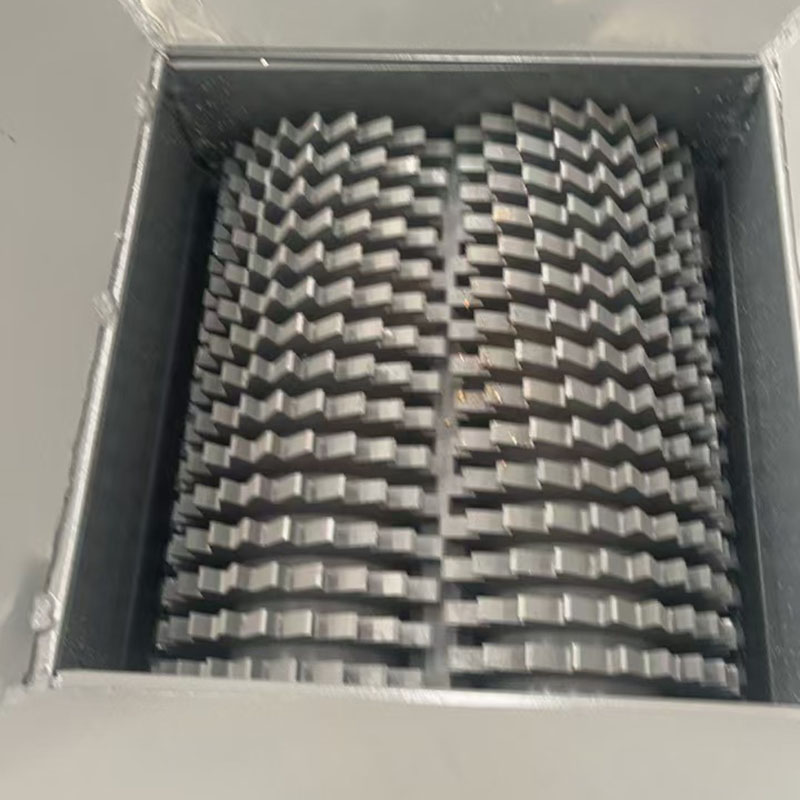

The machine features a robust hydraulic system that applies intense pressure to the raw materials within a mold, forming dense and uniform bricks. Advanced models are automated, ensuring precise control over dimensions and consistency in output. The resulting bricks exhibit excellent compressive strength, durability, and water resistance, meeting standard building material requirements.

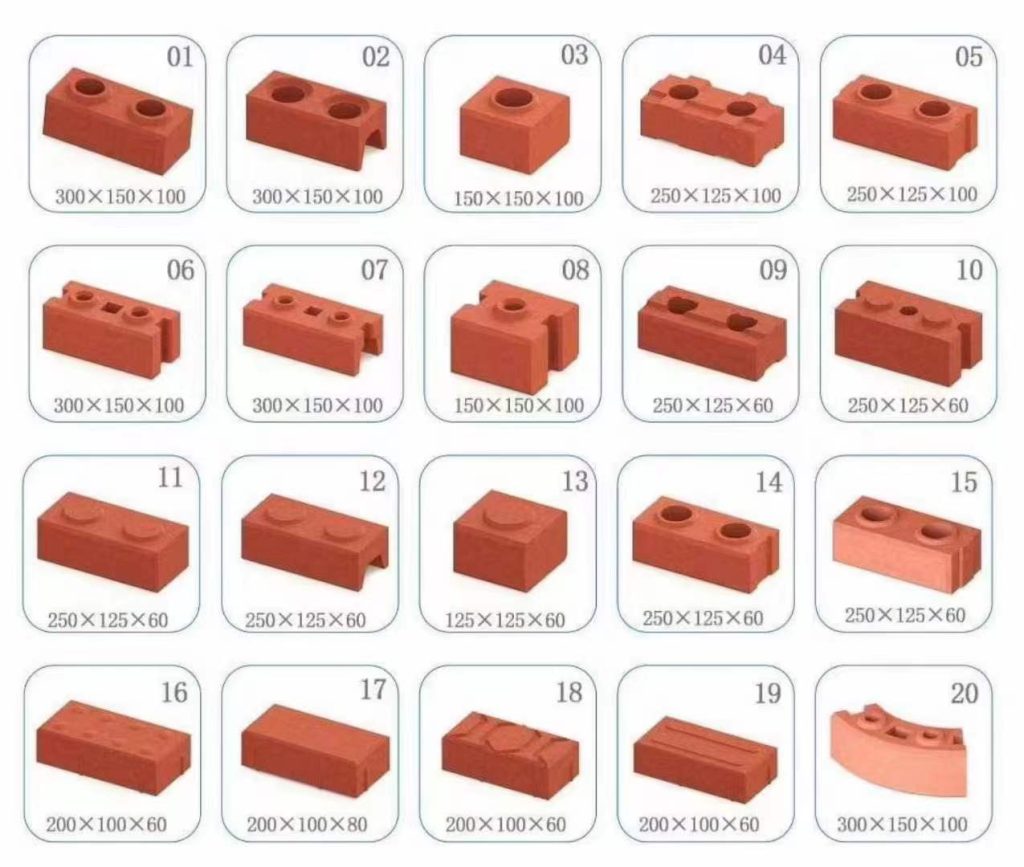

Key advantages include environmental sustainability, low operational cost, and versatility in raw material selection. It supports waste utilization and is ideal for producing various brick types, including solid, hollow, and paving blocks. This technology is widely adopted in green building projects and sustainable construction practices globally, offering an efficient solution for modern, eco-conscious infrastructure development.